Engineering and Design

GEM Engineering is a company established to form business partnerships in the Aegean Region in Turkey by performing engineering calculations and design of industrial plant machinery and equipment.

With its team of experienced engineers, the company provides machinery and equipment design and engineering calculations in compliance with international standards, primarily for the petrochemical industry.

Main areas of expertise include:

• Pressure Vessel Design and Engineering Calculations (ASME Section VIII Division 1, EN 13445, PED 2014/68/EU)

• Storage Tank Design and Engineering Calculations (API 650, API 620, EN 14015)

• Piping Stress Analysis (ASME B31.3, ASME B31.4, ASME B31.8, EN 13480)

• Natural Frequency Calculations for Rotating Equipment Piping

• Preparation of Piping Isometrics

• Hydraulic Calculations (pressure drop calculation, surge calculation, relief valve calculation, etc.)

• Equipment Flange Torque Calculations and Preparation of Torqueing Procedures

• Finite Element Analysis for Equipment Nozzles

• Local Stress Analysis for Equipment Nozzles (WRC107, WRC297)

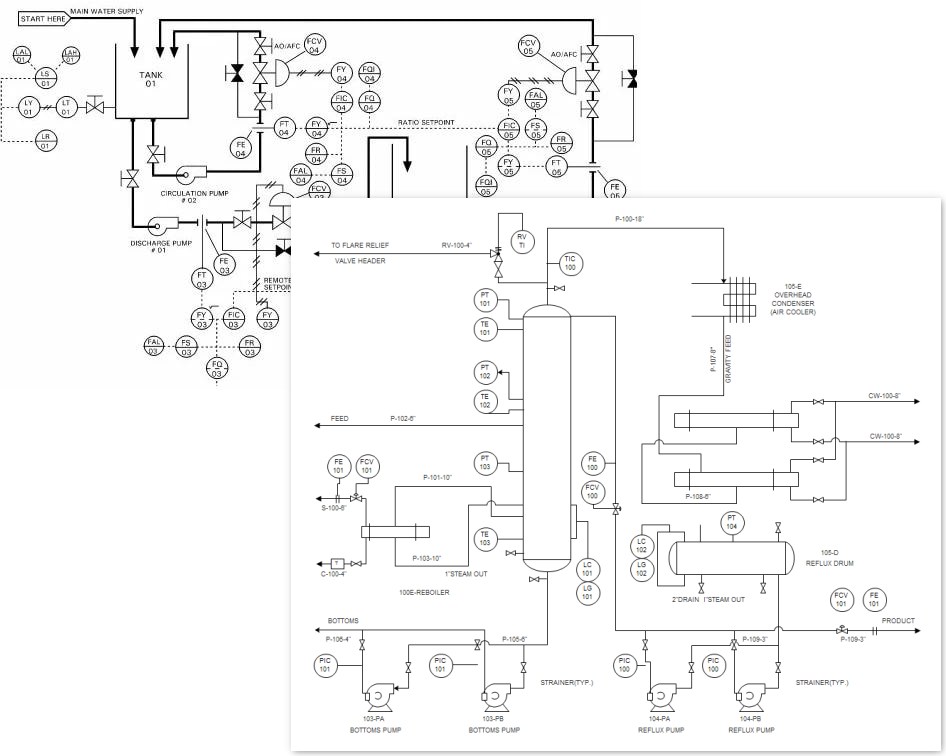

• Preparation of P&ID (Process and Instrumentation Diagram)

• Preparation of PFD (Process Flow Diagram)

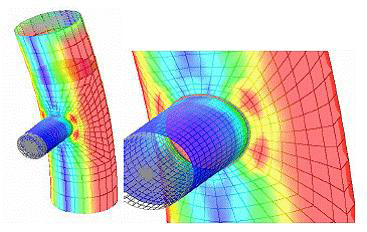

• Finite Element Analysis (FEA)

• Preparation of 3D Models

• Preparation of Machine/Equipment General Arrangement Drawings

• Preparation of Machine/Equipment Manufacturing Drawings

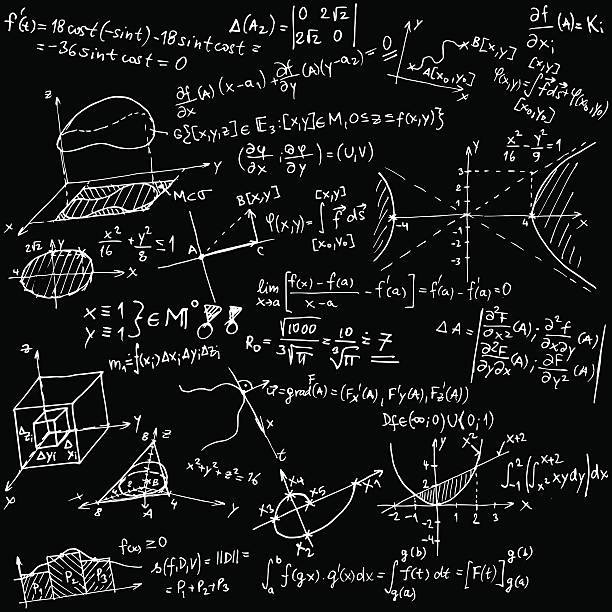

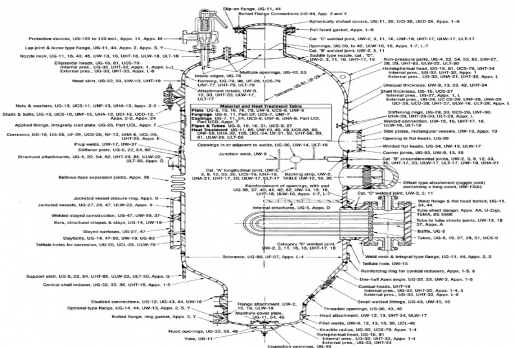

Pressure Vessel and Heat Exchanger Design and Engineering Calculation

GEM Engineering performs calculation and design work in accordance with ASME Section VIII Division 1, EN 13445, and PED 2014/68/EU standards.

Code requirements are reviewed based on the latest editions, ensuring that fabrication costs are kept to a minimum.

The calculation work is carried out using computer-aided software, specifically Intergraph PVElite and Codaware Compress.

In cases where the software is insufficient, a complete calculation report is prepared for our partners using Microsoft Excel spreadsheets.

Project requirements and customer specifications are thoroughly reviewed, and all requests are fully met through comprehensive calculation reports.

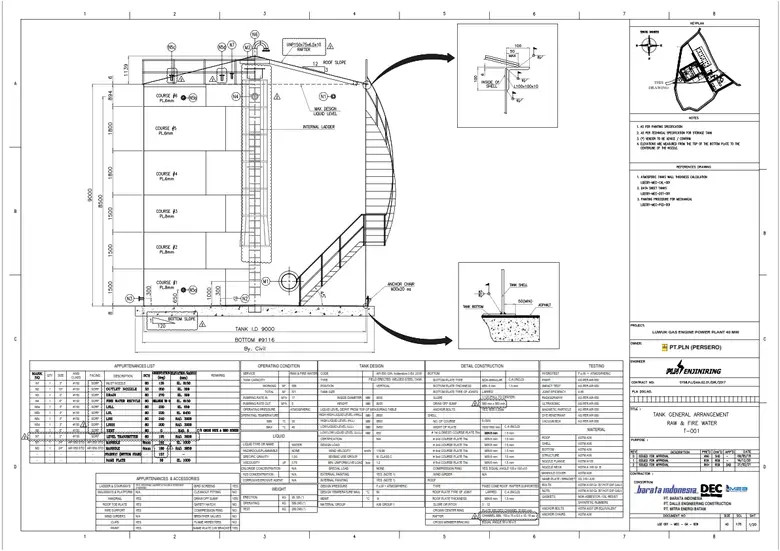

Storage Tanks Design and Engineering Calculations

GEM Engineering performs calculation and design work in compliance with API 650, API 620, and EN 14015 standards.

The calculations are carried out using computer-aided software, specifically AMETank software.

In cases where the software is insufficient, a complete calculation report is prepared for our partners using Microsoft Excel spreadsheets.

Equipment Nozzle Calculations

Equipment nozzle checks, including the verification of the loads and moments transferred from the piping to the nozzles, as well as the analysis of the stresses and effects caused by the nozzles on the equipment, are carried out in accordance with WRC 107, WRC 297, and ASME Section VIII Division 2 standards.

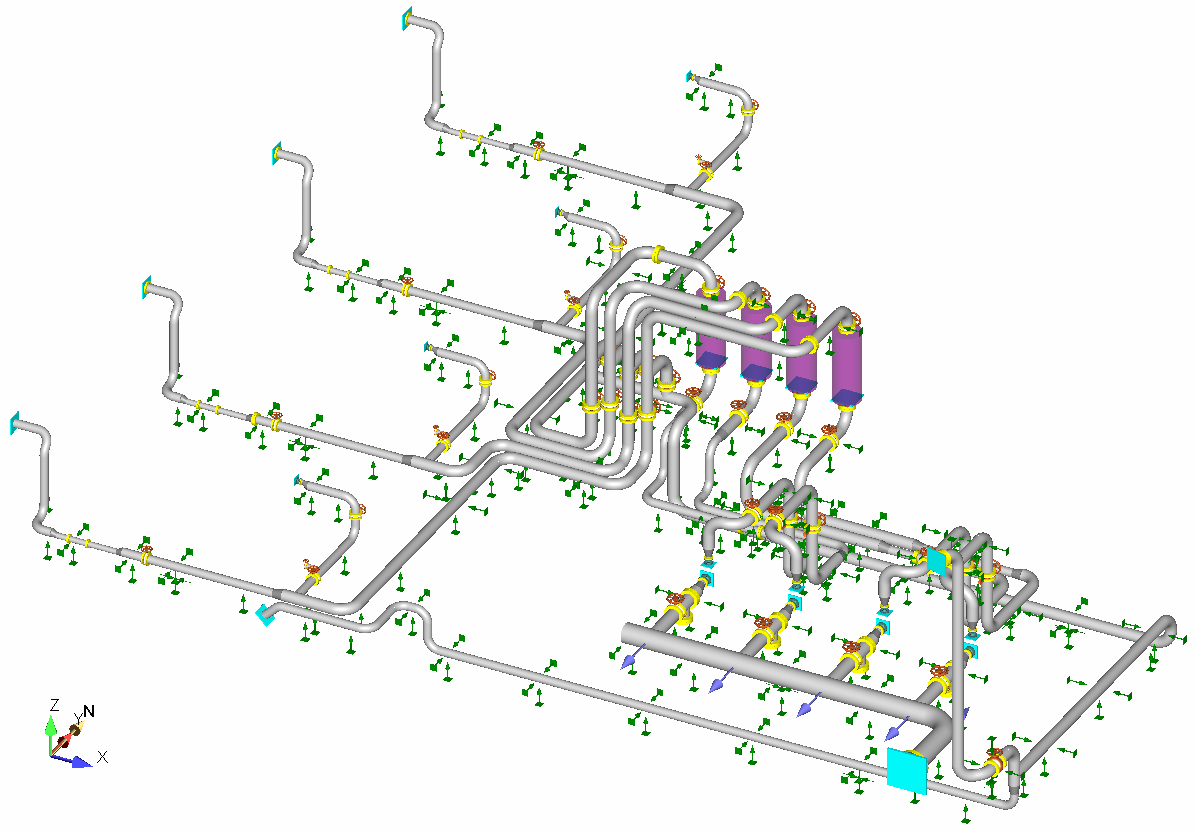

Pipe Stress Analysis

GEM Engineering performs calculation and design work in compliance with ASME B31.3, ASME B31.4, ASME B31.8, and EN 13480 standards. The calculations are carried out using computer-aided software, specifically Hexagon Caesar II.

A safe piping design is achieved through natural frequency analysis of the lines connected to rotating equipment within the facility, as well as flange leakage calculations.

Upon completion of the analysis, the piping design and engineering calculations, along with isometric drawings, are delivered to our partners as a comprehensive package in a single file.

Insutrial Facility Design

GEM Engineering provides support to its partners during the EE (Early Engineering) and EPC (Engineering - Procurement - Construction) phases of industrial plant projects in the following areas:

• Preparation of P&ID (Process and Instrumentation Diagram)

• Preparation of PFD (Process Flow Diagram)

• 3D Modeling

• Hydraulic Calculations (pressure drop calculation, surge calculation, relief valve calculation, etc.)

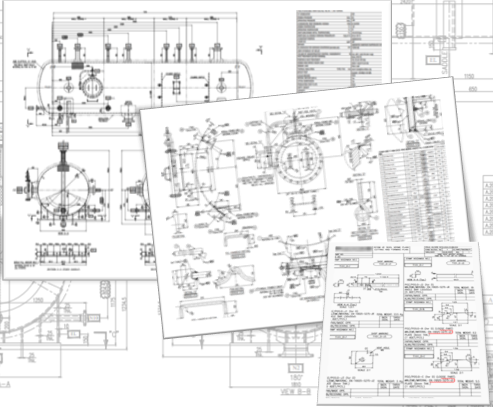

Preparation of the Machine/Equipment General Arrangement Drawings & Manufacturing Drawings

We prepare project drawings that support all disciplines, from project tracking to manufacturing, and from quality control documentation to shipment.

These project drawings are created using Autodesk AutoCAD, and a complete package of drawing files is prepared for the entire project.

A Comporate Identity Committed To The Quality Management System

GEM Engineering has adopted the ISO 9001 Quality Management System and carries out all its activities within this framework. The company manages traceability efforts, cost analyses, and process design through MS Project and MS Office programs, sharing real-time project traceability with its business partners.

We Are Your Solution Partner

The primary mission and purpose of GEM Engineering is partnership. We are not only a provider of technical support but also a trusted solution partner for our clients."

From identifying your challenges and problems to developing solutions, from technical support to comprehensive engineering services, and from design to production — we stand by your side at every stage of the process.

Contact

Welcome to GEM Engineering — we are here to support you with professional engineering services.

GEM ENGINEERING

7214 Street No:4A Özdere/İZMİR/TURKEY

+90 538 620 72 62

info@gemmuhendislik.com